Refund Guaranteed

Why choose us

T10 Steel

Forged Blade

Collector Quality

Trusted Globally

Inspired by Japan

Kumo Katana (T10 Steel & Hitatsura Hamon) - 雲刀

Included with your order

Note: Engraving placement and orientation may vary by blade model (hamon, geometry, and flat area).

Free Shipping over $250

No Bots, No AI

Refund Guaranteed

Free Shipping over $250

No Bots, No AI

Our team is here to help with any questions or concerns.

We’re always happy to assist you — don’t hesitate to reach out.

Why choose us

T10 Steel

Forged Blade

Collector Quality

Trusted Globally

Inspired by Japan

Kumo Katana (T10 Steel & Hitatsura Hamon) - 雲刀

Specifications

- Full tang in the handle

- SHARP blade

- Hand-forged

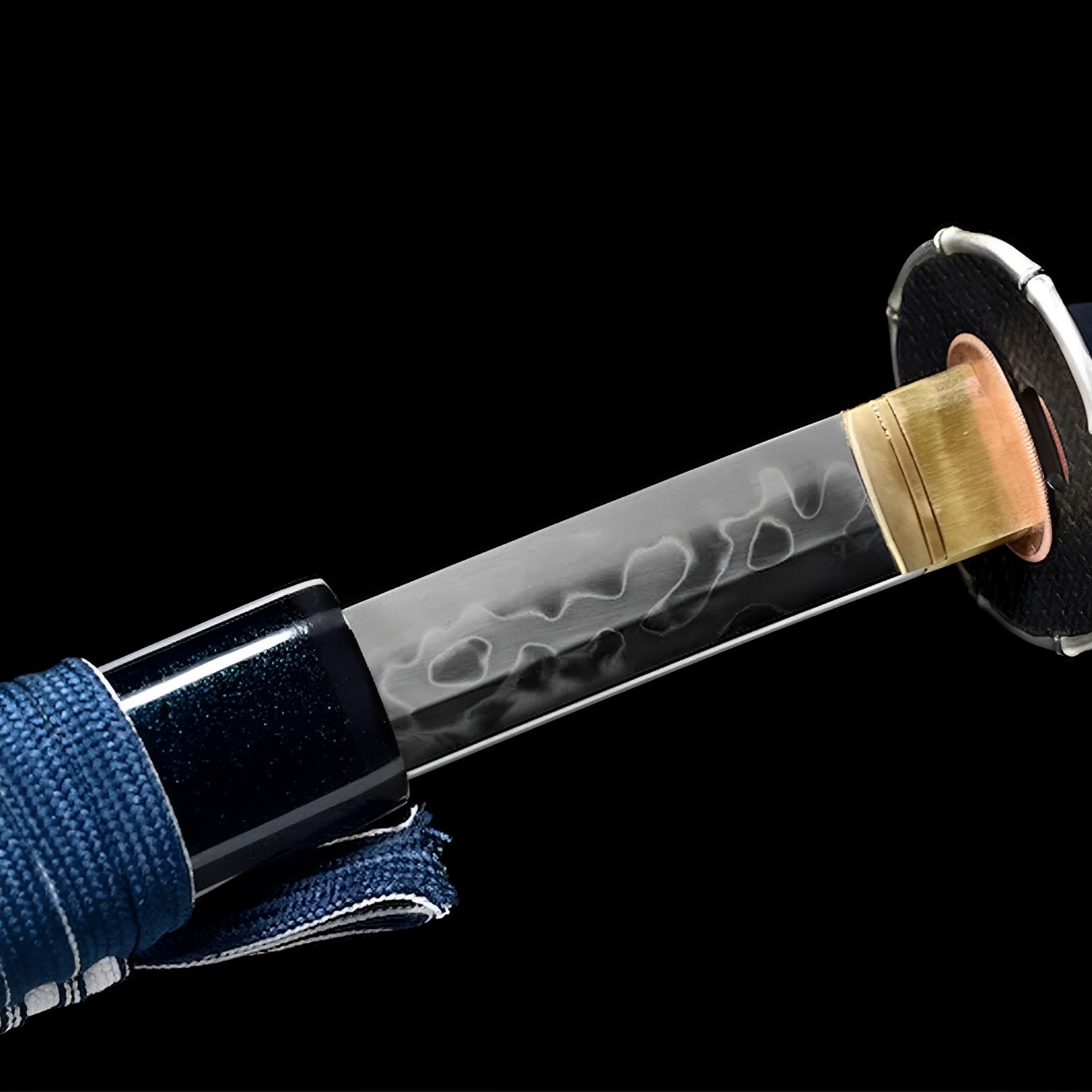

- Blade material: T10 Steel & Hitatsura Hamon

- Hand-polished

- Habaki material: Iron alloy

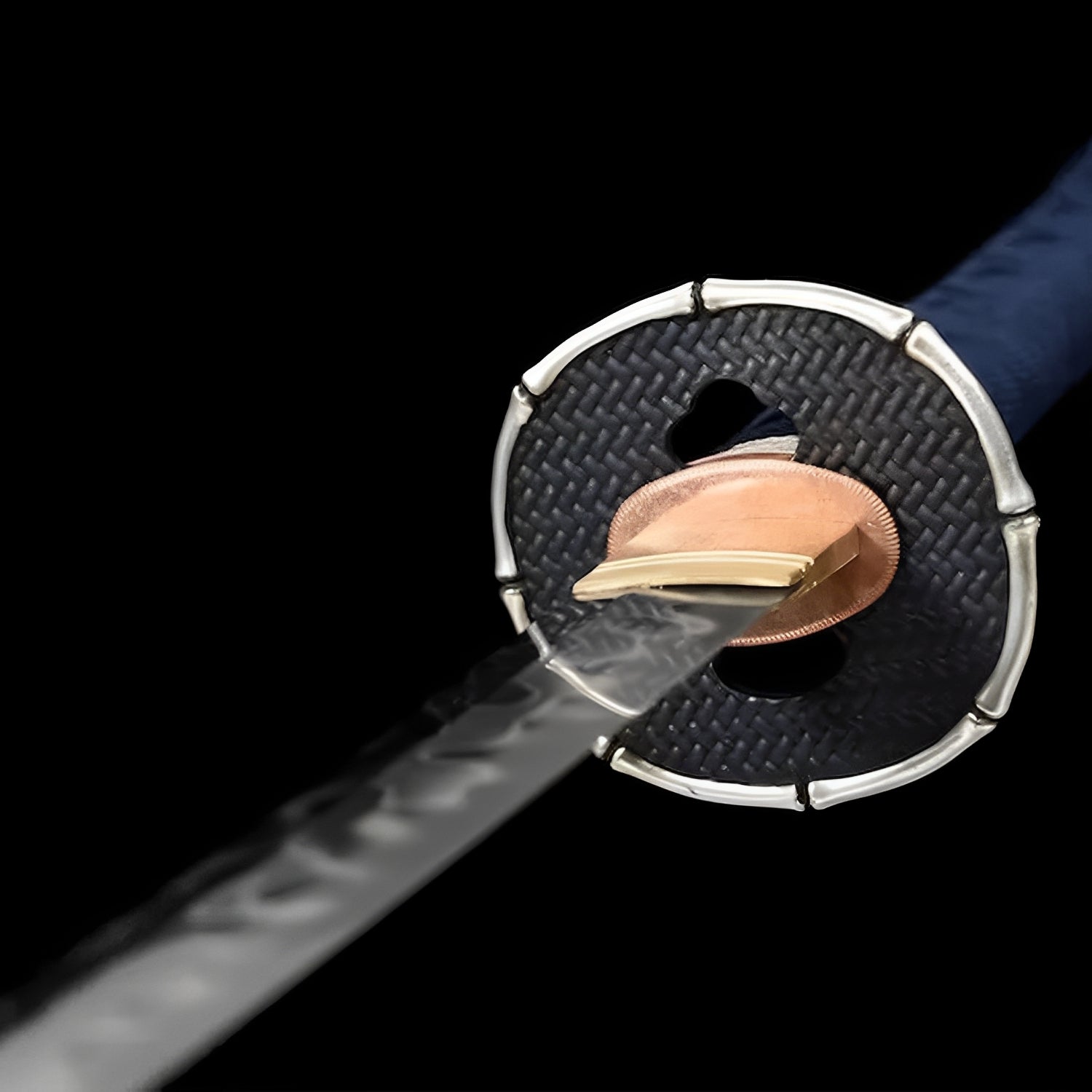

- Tsuba made of copper and silver

- Lacquered solid wood saya

- Koiguchi & Kurigata made of buffalo horn

- Solid wood tsuka wrapped in ray skin

- Tsuka-ITO made of cotton

- Total length: 105 cm

- Blade length: 72 cm

- Blade width: 3.2 cm

- Blade thickness: 0.7 cm

- Handle length: 30 cm

-

Included: Katana and its scabbard

Kumo Katana - Cloud Pattern Technical Mastery

Wield engineered precision with Kumo Katana, blade where metallurgy becomes philosophy. This technical T10 steel masterwork refuses decorative pretense - hitatsura hamon covering entire blade proving complete differential hardening mastery, cloud patterns emerging through controlled oxidation not paint, navy wrapping suggesting sky where clouds drift eternally, the entire piece embodying principle that greatest beauty emerges from perfect function, asking whether you collect swords appreciating surface aesthetics or understand metallurgical complexity determining whether blade cuts once brilliantly then fails versus cutting thousand times maintaining edge that could shave arm hair after decade's hard use.

T10 High-Carbon Steel Foundation

T10 steel represents specific metallurgical choice balancing performance against practicality - approximately 1.0% carbon content creating alloy hard enough holding razor edge yet tough enough resisting catastrophic failure, the composition achieving sweet spot where hardness enables cutting performance while retained flexibility prevents brittleness causing blade shattering under impact. This precision alloy blade channels centuries of metallurgical evolution into modern steel grade combining best properties historical smiths achieved through folding with consistency only industrial process enables.

The "T" designation indicates tool steel grade - material designed for cutting tools, industrial applications demanding edge retention under repeated stress, the classification itself proving this isn't decorative metal but functional material engineered for specific performance parameters. Where stainless steels prioritize corrosion resistance sacrificing hardness, where pure high-carbon steel achieves extreme hardness risking brittleness, T10 occupies optimized middle ground suitable for swords requiring both cutting ability and structural integrity.

Specifically, T10's carbon content (0.95-1.05%) enables achieving 58-60 HRC (Rockwell Hardness Scale) after proper heat treatment - hardness level where edge retention exceeds softer steels dramatically while avoiding extreme brittleness plaguing steels above 62 HRC. That narrow hardness window requires precise heat treatment: too soft and edge rolls during cutting, too hard and blade chips catastrophically, the difference between functional weapon and expensive paperweight determined by temperature control during quenching measured in degrees not ranges.

Traditional Japanese sword steel (tamahagane) achieved similar performance through labor-intensive folding eliminating impurities, the repeated heating and hammering homogenizing carbon content while removing slag. Modern T10 steel achieves comparable purity through controlled smelting, the industrial process enabling consistency impossible for historical smiths whose steel quality varied batch to batch. The modern precision blade proves that respecting traditional performance goals doesn't require exclusively using traditional methods when contemporary metallurgy achieves superior consistency.

Technical collectors specifically appreciate steel grade specifications, understanding that "high-carbon steel" generic description masks enormous performance differences - 1095 steel differs dramatically from T10 despite both being high-carbon, the specific alloy composition and heat treatment protocols determining whether you own sharp decoration or functional cutting tool capable maintaining edge through actual use.

Hitatsura Hamon Mastery

Hitatsura (沸頭 - "all over") represents rarest, most difficult hamon pattern - instead of temper line appearing only along cutting edge (standard hamon), the entire blade surface shows hardening activity, crystalline structures called nie and nioi covering blade from edge to spine creating all-over patterning impossible achieving without extraordinary skill. This complete hardening blade demonstrates smith's absolute control over heat treatment, the hitatsura proving mastery because slight temperature variation during quenching prevents pattern forming, the technique requiring perfection where standard hamon tolerates minor imperfection.

Traditional Japanese smiths considered hitatsura among most prestigious achievements - only master-level craftsmen attempted it because failure rate remained high even for experienced hands, the pattern either appearing completely or not at all, no middle ground between success and expensive failed blade requiring re-forging. Historical swords showing genuine hitatsura commanded premiums because rarity and difficulty signaled exceptional skill.

The specific cloud-like patterns within hitatsura create visual justification for "Kumo" (cloud) naming - the nie crystals cluster forming shapes resembling cumulus clouds drifting across steel sky, natural randomness creating organic beauty impossible predicting or controlling completely, each blade therefore becoming unique even when smith uses identical process. That unpredictable beauty-within-control epitomizes Japanese aesthetic principles: perfecting technique enables natural variation emerging spontaneously, forcing perfection would destroy the organic quality making result beautiful.

Modern metallurgy understands hitatsura's mechanism - rapid quenching causes steel crystallizing throughout blade thickness rather than only at surface, the dramatic temperature differential between red-hot steel and quenching medium creating crystalline structures extending deeper than standard edge-quenching achieves. That scientific understanding doesn't diminish achievement; it amplifies appreciation for smiths achieving it without thermometers, relying instead on color-temperature judgment developed across decades of experience.

The crystalline art blade proves that functional metallurgy can achieve aesthetic excellence - the hitatsura isn't applied decoration but inherent material property revealed through proper treatment, the beauty emerging from steel's molecular structure rather than being added afterward, the ultimate fusion of form following function creating form that transcends function.

Cloud Symbol Philosophy

Kumo (雲 - cloud) carries layered meaning in Japanese culture beyond literal meteorological phenomenon - clouds represent transience (constantly forming, changing, dissipating), freedom (drifting without fixed destination), perspective (same cloud appears different from varied viewpoints), mystery (obscuring what lies beyond while creating beauty through that obscuration). The cloud philosophy blade channels those conceptual associations, naming itself after natural phenomenon embodying complex philosophical ideas.

Specifically, clouds represent mu (無 - emptiness/nothingness) in Zen Buddhism - they exist yet lack substance, they're visible yet intangible, they demonstrate impermanence perfectly by never maintaining identical form across sequential moments. That philosophical resonance transforms simple nature reference into profound meditation on existence's nature: solid-seeming things (like steel blade) ultimately prove as transient as clouds, current form being temporary state within endless transformation.

Traditional Japanese poetry extensively employed cloud imagery - clouds concealing mountain peaks suggested hidden truths, clouds parting revealed sudden clarity, clouds gathering warned of coming storms, the meteorological observation becoming metaphorical vocabulary discussing human experience. The named blade therefore participates in centuries of literary tradition using natural imagery conveying emotional/philosophical content.

The specific hitatsura pattern resembling clouds creates perfect name-form alignment - the blade isn't merely called cloud but shows clouds through steel's crystalline structure, the naming describing visible reality rather than imposing arbitrary association, that integration of name and nature demonstrating thoughtful design where every element reinforces unified vision.

Navy Depth Aesthetic

The deep navy wrapping and saya create sophisticated color choice evoking sky where clouds drift - not bright daytime blue suggesting cheerfulness but twilight navy suggesting contemplation, depth, the liminal moment between day and night where clouds transform from white to gray to invisible. This contemplative depth blade uses color psychologically, the navy preventing brightness from becoming frivolous, grounding cloud imagery in substantial darkness.

Unlike aggressive reds demanding attention or pure blacks refusing it, navy occupies middle ground - noticeable without screaming, sophisticated without being pretentious, masculine without being macho, the color working across contexts from traditional Japanese rooms to modern minimalist spaces. That versatility matters for collectors needing swords integrating into varied environments, where blade must justify presence aesthetically regardless of surrounding style.

Traditional Japanese indigo dyeing achieved similar navy tones through natural processes, the deep blues created from indigo plant fermentation representing significant technical achievement given dye's complexity and expense. Modern navy wrapping honors that tradition while benefiting from synthetic dyes' colorfastness, the contemporary materials enabling traditional aesthetic without traditional maintenance burden.

The navy specifically complements hitatsura's silver-gray pattern perfectly - cool blue against cool gray creates harmonious palette avoiding color clash, the restrained combination letting metallurgical artistry dominate rather than competing through garish accent colors. That design discipline demonstrates understanding that when you possess extraordinary blade pattern, surrounding elements should enhance not distract.

Functional Collector Grade

This performance focus piece serves collectors appreciating swords as functional tools first, display pieces second - those who might actually test-cut with their blades, who understand cutting tatami mats reveals whether sword possesses proper geometry and heat treatment, who recognize that authentic evaluation requires using tool for intended purpose rather than merely admiring appearance.

The T10 steel specification particularly matters for functional use - this isn't stainless steel that would dull quickly, isn't mild steel that wouldn't hold edge, isn't ultra-hard steel that would chip on bone contact, but carefully selected alloy proven through tool-making applications to balance hardness, toughness, edge retention. That practical consideration elevates blade beyond decoration into realm of serious cutters who demand performance matching appearance.

Traditional martial artists specifically seek hitatsura blades for training because complete hardening provides consistent cutting feel throughout blade length - no differential flex between hard edge and soft spine causing unpredictable blade behavior during cuts, the uniform hardness creating reliable feedback teaching proper cutting mechanics. That functional advantage explains why historical warriors sometimes preferred hitatsura despite rarity driving costs higher than standard differential hardening.

Investment value specifically favors functional-grade pieces as martial arts practice grows globally - modern practitioners want training with quality tools, not wall-hangers, the demand for actually usable swords creating market supporting premium pricing for properly constructed blades. Collectors recognizing that trend position themselves owning pieces appreciating both aesthetically and as functional implements serving actual martial traditions.

The practitioner blade particularly appeals to those who've progressed beyond pure collecting into actual martial study, who've learned through handling many swords to distinguish quality from pretense, who understand that expensive doesn't always mean good but good always justifies investment through performance delivering what appearance promises.

Care Instructions: Maintain this technical masterwork understanding T10 steel requires specific care protocols. After any handling, wipe blade with clean cloth removing skin oils containing acids that will cause oxidation despite steel's carbon content. Apply thin sword oil coat (choji oil traditional, modern gun oils work) preventing rust - high-carbon steel WILL rust without protection, this isn't stainless requiring no maintenance. Inspect hitatsura pattern regularly using magnification appreciating crystalline structure's beauty while checking for early oxidation spots requiring immediate attention. The navy wrapping benefits from periodic inspection ensuring no moisture trapped causing mildew; re-wrap if necessary using proper tsukamaki technique (find tutorials - incorrect wrapping causes handle failure). Store in climate-controlled environment; temperature extremes stress steel causing micro-cracks accumulating into catastrophic failure across decades. If you test-cut, clean blade IMMEDIATELY after use - organic materials (tatami, bamboo, clay) contain acids aggressively attacking steel if left on surface. Handle knowing this represents intersection of traditional Japanese metallurgy with modern materials science, that hitatsura pattern required skill level few smiths achieve, that T10 steel was engineered specifically for cutting tool applications. This isn't decorative wall-hanger but functional blade capable performance matching traditional tamahagane swords when properly maintained and used. The clouds remind: beauty and function needn't oppose but can synthesize when craftsman understands both deeply enough honoring each equally.

T10 steel. Hitatsura mastery. Cloud patterns emerge. Function achieves beauty through engineering precision.

Legal Disclaimer

By purchasing from Katana Corp, you acknowledge and agree that:

- You are at least 18 years of age (or the age of majority in your jurisdiction).

- You are solely responsible for verifying and complying with all local laws and import regulations before placing an order.

- Some countries prohibit the importation of swords entirely. Katana Corp is not responsible for orders delayed, seized, or refused by customs authorities.

- All katanas and related products are sold strictly as decorative and display items. They are not intended or certified for combat use.

- Depending on the jurisdiction, swords may legally be considered bladed weapons, subject to specific restrictions or prohibitions.

- Katana Corp disclaims all liability for any injury, damage, or legal consequences resulting from misuse, abuse, or unlawful use of its products.

For full details, please refer to our Terms of Service.

Care & Maintenance

To maintain your katana's appearance and performance over time, we recommend:

- Regularly wiping the blade with a soft cloth to remove fingerprints and moisture.

- Applying a light coat of choji oil to prevent rust (for carbon steel blades).

- Storing the sword in a dry place, preferably inside its saya.

- Avoiding direct contact with hard surfaces to preserve sharpness and finish.

For more care tips, check our full maintenance guide in the FAQ section.

Behind the Blade

Every katana we offer carries the essence of centuries-old craftsmanship.

More than just a weapon, the katana symbolizes discipline, honor, and mastery.

Our artisans draw inspiration from traditional forging methods to ensure each blade reflects the spirit of the samurai — strength, precision, and soul.

Owning one is not just about aesthetics — it’s about carrying a piece of that legacy.

User Experience

This katana is designed to offer a perfect balance between blade and handle.

Its ergonomic tsuka (handle) allows a secure two-handed grip, while the weight distribution ensures smooth, fluid movement.

Whether for training, display or cutting practice, handling feels natural and precise.

The Art of Traditional Forging

Each katana we craft is born from centuries of samurai tradition.

Our master smiths shape every blade by hand, folding the steel to achieve unmatched strength, flexibility, and beauty.

This time-honored process is not just about creating a weapon? it’s about preserving a legacy of discipline, honor, and artistry.

Materials Chosen Without Compromise

We select only the highest-grade steels and authentic fittings to ensure every katana is both a masterpiece and a reliable companion.

From the flawless hamon line to the perfectly balanced tang, each detail is carefully inspected to meet the highest standards of performance and aesthetics.

More Than a Sword, A Lifelong Legacy

Owning a handmade katana is an experience that goes beyond the blade itself. It’s holding history, tradition, and craftsmanship in your hands.

Whether displayed as a work of art or wielded with precision, your katana will stand as a symbol of timeless skill and dedication for generations to come.

-

Key Destinations

United States: 5–7 days

Canada: 5–7 days

Australia: 6–9 days

Denmark: 4–6 days

Netherlands: 3–5 days

Sweden: 4–6 days

Switzerland: 3–5 days

Finland: 5–7 days

Singapore: 6–8 days -

Central European Partners

France: 2–3 days

Germany: 3–5 days

Spain: 4–6 days

Italy: 4–6 days

Belgium: 3–5 days

Austria: 4–6 days

Ireland: 4–6 days

Poland: 4–6 days

Portugal: 4–6 days -

Extended EU Network

Czechia: 4–6 days

Hungary: 4–6 days

Slovakia: 4–6 days

Slovenia: 5–7 days

Romania: 5–7 days

Bulgaria: 5–7 days

Croatia: 5–7 days

Serbia: 5–7 days

Estonia: 5–7 days

Latvia: 5–7 days

Lithuania: 5–7 days

Luxembourg: 3–5 days

Greece: 5–8 days -

FAQ’s

Visit our FAQs page to find answers to common questions.