The katana is more than a sword, it's a cultural icon, a spiritual artifact, and the embodiment of centuries of Japanese craftsmanship. Behind every real katana lies an intense process rooted in tradition, precision, and ritual. From the smelting of tamahagane steel to the final polish of the blade, the forging of a katana is as much an art form as it is a technical discipline. In this article, we take you inside the sacred world of katana forging, step by step, revealing the secrets that turn raw metal into a soul-bound weapon.

Tamahagane: The Steel of Legends

At the heart of every authentic katana is tamahagane, a high-carbon steel created from iron sand (“kanze") smelted in a traditional clay furnace called a tatara. This process, which can last up to 72 hours, produces a blend of steels with varying carbon contents. Only the best slices of this steel, those with the ideal balance of hardness and flexibility, are selected by the swordsmith.

Tamahagane is not mass-produced. It is labor-intensive, expensive, and rare. That rarity contributes to the katana's mystique and historical status as a symbol of the samurai's soul. Tamahagane also holds spiritual significance, swordsmiths often view the steel as something living, a raw potential waiting to be shaped into a weapon of honor and legacy.

Preparing the Steel: Folding and Purification

Before forging begins, the steel is repeatedly folded and hammered, often as many as 15 times. This creates thousands of layers and helps eliminate impurities. The process doesn’t just purify the metal, it distributes carbon evenly, ensuring the blade won’t be brittle or too soft.

This folding also produces the beautiful hada, or grain pattern, visible on the surface of the blade, a fingerprint of the smith's skill. Different schools of swordsmithing have distinct folding styles, resulting in unique patterns that are used to trace the lineage of a blade. Folding also reveals the depth of mastery: a poorly folded blade is structurally weak and less beautiful.

Forging the Blade: Fire and Precision

Once folded, the swordsmith shapes the steel into a billet and forges the core and jacket of the blade. In traditional kobuse or maru construction, softer steel forms the core, while harder steel encases it. This duality provides both resilience and cutting power. The forging must be done at precise temperatures, too hot, and the steel loses its structure; too cold, and it becomes unworkable.

The smith constantly adjusts the heat of the forge and rhythm of the hammer strikes. Watching a master at work is witnessing a dance with fire, a careful negotiation between discipline and intuition. The blade gradually takes shape, and the smith determines the curvature not by force but by preparing for the next transformative step: quenching.

Differential Hardening and the Hamon Line

One of the most distinctive features of a katana is its hamon, the wavy line along the blade edge. This is the result of differential hardening, where a clay mixture is applied to the blade before quenching. The edge, left exposed, cools quickly and becomes harder. The spine, covered in thicker clay, cools slowly and remains softer.

This technique prevents the blade from snapping under pressure while ensuring it retains a razor-sharp edge. The visible hamon is not just functional; it's an artistic hallmark of the smith. Common styles include suguha (straight), midare (irregular waves), and notare (gentle undulations), each with symbolic or aesthetic meaning. Sword collectors often prize hamon above all else, as it reflects the individual spirit of the blade.

Polishing: Revealing the Blade's True Character

After quenching, the blade is passed to a professional togishi, or sword polisher. Polishing is not cosmetic. It reveals the grain pattern, sharpens the edge, and refines the hamon. The process takes weeks and involves multiple grades of whetstone, each stage requiring incredible control.

Polishing is a sacred trust. The togishi must understand the intention behind the blade’s geometry. They adjust the kissaki (tip), the shinogi (ridge line), and even the reflection of light across the ji (surface). The final result isn't just beautiful, it's a blade that cuts cleanly, gleams with artistry, and reflects centuries of tradition.

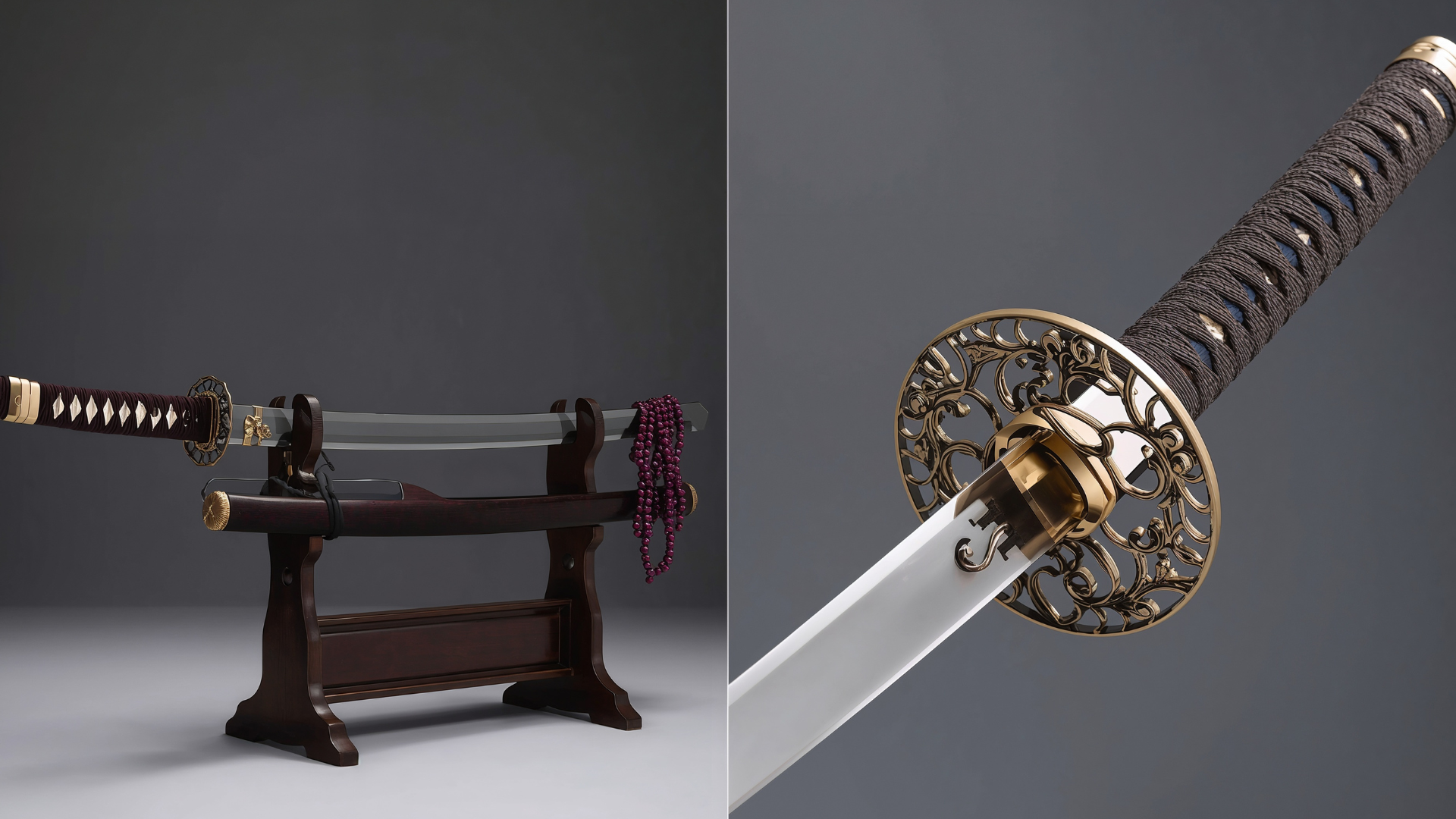

Mounting the Katana: Saya, Tsuba, and Tsuka

Once polished, the blade is ready for mounting. Traditional katana fittings are crafted by artisans specializing in specific parts:

-

Tsuka (handle): Usually made from wood, wrapped in rayskin and silk cord

-

Tsuba (guard): Both decorative and functional, often handcrafted

-

Saya (scabbard): Lacquered wood designed to protect the blade

These are not mere accessories, they affect the balance and use of the sword. The tsuka must be fitted tightly to avoid vibration during strikes. The tsuba is often custom-engraved with imagery reflecting the warrior's clan, beliefs, or aspirations. Some modern smiths even collaborate with lacquer artists and metalworkers to produce one-of-a-kind masterpieces.

The Swordsmith's Signature: Mei and Legacy

Authentic katana are signed by the smith on the tang (nakago) using a chisel. This mei includes the swordsmith's name, school, and sometimes the date. The tang is never polished, preserving the signature and aging of the metal as proof of authenticity.

The swordsmith’s name carries weight. Some are designated Living National Treasures, while others are part of centuries-old lineages. A signed katana is a statement: this blade was crafted by human hands, with pride, legacy, and skill.

Katana Forging Schools and Their Differences

Throughout Japanese history, different regions developed distinct forging techniques and aesthetics. The Gokaden, or Five Traditions, include:

-

Yamato: Known for straight blades and utilitarian strength

-

Yamashiro: Refined hamon and elegant shapes

-

Bizen: Balanced blades, popular among samurai

-

Soshu: Robust construction, used in battle

-

Mino: Hybrid techniques from multiple regions

Each school left a mark on katana history. Modern swordsmiths often draw inspiration or training from these lineages, creating blades that reflect centuries of accumulated wisdom.

The Role of Apprenticeship in Katana Forging

Becoming a swordsmith in Japan is no small feat. A formal apprenticeship can last up to five to seven years, during which the apprentice lives and works under a licensed master. Tasks begin with sweeping floors and progress to forging under strict guidance. The licensing exam, supervised by the Agency for Cultural Affairs, is rigorous and requires the forging of a flawless blade.

This tradition ensures quality and continuity. It also fosters humility, no matter how talented, every smith begins by honoring those who came before.

Sacred Objects: The Spiritual Side of Katana

In Shinto tradition, forging a katana is a sacred act. Many smiths purify themselves before beginning. The tatara is treated with respect, sometimes even blessed by priests. Some swordsmiths consider the final product to house a spirit, one forged not just from steel, but from intention, discipline, and legacy.

Katanas have been offered to shrines, used in weddings, and passed down as heirlooms imbued with spiritual weight. Some temples in Japan still host ceremonies where new swords are blessed. To many, the katana is not simply a weapon, it is a conduit of ancestral power.

Modern Katana Forging: Preserving a Dying Art

Today, authentic katana forging is regulated in Japan. Only licensed swordsmiths may produce real katanas, and they are limited to crafting a small number each year. Organizations like the Nihon Bijutsu Token Hozon Kyokai (NBTHK) protect and certify traditional blades.

Swordsmithing schools such as Bizen, Soshu, and Yamato continue to practice their historical forging styles. Global interest in Japanese swords has also led to international apprenticeships, museum partnerships, and modern forges abroad attempting to replicate the process.

FAQ: All About Katana Forging

How long does it take to forge a real katana?

From smelting to mounting, an authentic katana can take several months to complete.

Can anyone learn to forge a katana?

In Japan, you must undergo an apprenticeship and receive a license to legally forge swords.

Why is tamahagane steel so special?

Its controlled carbon content, purity, and traditional smelting process make it ideal for swords.

Are modern katanas as good as historical ones?

Yes, when made by licensed smiths using traditional methods, they match or exceed historical standards.

What is the average price of a real forged katana?

Prices range from $5,000 to $50,000 depending on the smith, materials, and craftsmanship.

What is the purpose of the hamon?

It visually marks the differential hardening line and indicates a well-crafted edge.

Do swordsmiths consider their work spiritual?

Many do. For them, forging a blade is a sacred, even meditative act.

Final Thoughts: The Blade That Carries a Soul

Forging a katana is more than metallurgy, it's a ritual. From the fire of the forge to the final polish, every step is guided by discipline, reverence, and the pursuit of perfection. In a world driven by speed and mass production, the katana remains a timeless reminder of what it means to create something with soul.

Whether you collect, train, or simply admire from afar, understanding the forging of a katana brings you closer to the spirit of the samurai.

Share:

Do Samurai Still Exist in Japan?

Katana vs Tachi: Understanding the Ancestry of the Samurai Sword